Modular Architecture Revolutionizes Urban Development

The Prefabrication Paradigm Shift

Urban landscapes worldwide are undergoing a silent revolution as modular architecture evolves from utilitarian solution to sophisticated design strategy. This transformative approach to building—constructing components in controlled factory environments before assembling them on-site—is reshaping how cities grow, adapt, and function. Moving beyond its historical association with temporary or low-cost structures, contemporary modular design now delivers everything from luxury residential towers to cutting-edge cultural institutions with unprecedented speed, quality, and sustainability. The convergence of digital fabrication, innovative materials, and urgent urban challenges has propelled modular construction from niche alternative to mainstream movement, offering solutions to housing shortages, construction waste, and the accelerating pace of urban change. This comprehensive analysis explores how modular trends are redefining urban development, the technologies driving this transformation, and the profound implications for how we will build and inhabit future cities.

A. The Modular Renaissance: Drivers Behind the Resurgence

Multiple converging factors have elevated modular architecture from practical necessity to strategic advantage in urban development.

A.1. Urbanization Pressures and Housing Crises

Rapid urban population growth has created unprecedented demand for efficient construction methods.

-

Accelerated Delivery Timelines: Modular construction can reduce project timelines by 30-50%, critically important for cities needing to quickly address housing shortages and accommodate growing populations.

-

Predictable Cost Control: Factory-based production minimizes weather delays, theft, and other variables that typically cause budget overruns in conventional construction, providing greater financial certainty for developers and municipalities.

-

Density Optimization: Modular techniques enable efficient construction on challenging urban sites—narrow lots, irregular shapes, or constrained locations—where traditional construction would be impractical or prohibitively expensive.

A.2. Sustainability Imperatives and Resource Efficiency

The construction industry’s environmental impact has spurred interest in more efficient building methods.

-

Dramatic Waste Reduction: Factory precision cutting and material optimization typically reduce construction waste by 70-90% compared to site-built construction, addressing a major source of urban landfill volume.

-

Enhanced Energy Performance: Controlled factory conditions enable tighter tolerances and superior insulation installation, resulting in buildings with significantly higher energy efficiency and lower operational carbon emissions.

-

Lifecycle Flexibility and Adaptability: Modular buildings can be reconfigured, expanded, or disassembled for relocation, supporting circular economy principles rather than the traditional “build, use, demolish” cycle.

A.3. Technological Enablers and Quality Advancements

Digital technologies have overcome historical limitations of modular construction.

-

BIM Integration: Building Information Modeling allows complete digital prototyping before fabrication begins, ensuring perfect coordination between systems and components.

-

Robotic Fabrication: Automated manufacturing enables precision and complexity previously impossible in modular construction, supporting sophisticated architectural expression.

-

Quality Control Enhancement: Factory production eliminates weather exposure during critical construction phases and enables consistent quality verification throughout manufacturing, resulting in higher overall building performance and durability.

B. Modular Typologies and Urban Applications

Modular architecture has evolved diverse applications tailored to specific urban contexts and needs.

B.1. Residential Solutions Across Market Segments

Modular construction is delivering housing solutions from affordable to luxury markets.

-

Micro-Unit Developments: Projects like Carmel Place in New York demonstrate how modular construction can efficiently create compact, high-quality housing that addresses urban affordability challenges while maintaining design excellence.

-

Luxury Modular Towers: High-end residential projects such as 461 Dean Street in Brooklyn prove that modular techniques can deliver premium finishes and sophisticated designs, challenging perceptions that prefabrication compromises quality or aesthetics.

-

Mixed-Income Housing: Modular construction enables economically viable inclusion of affordable units within market-rate developments by reducing construction costs and timelines, supporting socioeconomically diverse communities.

B.2. Commercial and Institutional Applications

Beyond housing, modular methods are transforming how cities build workplaces, healthcare facilities, and educational institutions.

-

Adaptive Office Spaces: Modular commercial buildings can be reconfigured as tenant needs change, supporting evolving work patterns and reducing vacancy periods during tenant transitions.

-

Healthcare Facility Expansion: Hospitals are using modular construction for rapid expansion of treatment spaces, with projects completed in months rather than years—critically important during public health emergencies.

-

Educational Infrastructure: School districts are deploying modular classrooms that offer superior acoustic performance, natural lighting, and healthy materials compared to traditional portable classrooms, supporting better learning environments during enrollment fluctuations.

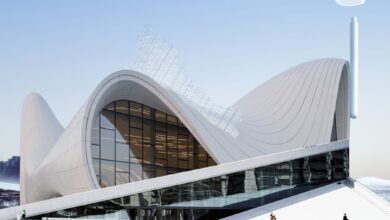

B.3. Civic and Cultural Buildings

Even complex building types with unique requirements are embracing modular strategies.

-

Rapid-Deployment Community Facilities: Libraries, community centers, and recreational facilities can be deployed quickly in developing neighborhoods, supporting community needs years earlier than conventional construction would allow.

-

Cultural Infrastructure: Projects like the Museum of Modern Art’s modular expansion demonstrate that sophisticated architectural statements can be achieved through prefabrication, even for institutions with exacting environmental and aesthetic requirements.

-

Emergency and Transitional Structures: Modular construction provides dignified temporary housing, medical facilities, and community spaces following natural disasters or during urban renewal projects.

C. Technological Innovations Driving Modular Advancement

Cutting-edge technologies are expanding what’s possible with modular architecture and construction.

C.1. Digital Design and Fabrication Technologies

Advanced software and manufacturing technologies enable new levels of modular sophistication.

-

Generative Design Algorithms: AI-driven systems can optimize module configurations for specific sites, programs, and performance requirements, exploring thousands of alternatives to identify optimal solutions.

-

Robotic Assembly Systems: Automated factories use robotics for precise, efficient assembly of modules, incorporating complex systems integration that would be challenging with manual labor.

-

Digital Twin Technology: Virtual replicas of modular buildings enable better facilities management, support future reconfiguration planning, and provide valuable data for improving future modular designs.

C.2. Material Science Innovations

New materials are enhancing modular building performance and expanding design possibilities.

-

Mass Timber Revolution: Cross-laminated timber and other engineered wood products offer structural capabilities comparable to concrete and steel with significantly lower carbon footprint, ideal for factory production.

-

Advanced Composite Materials: Fiber-reinforced polymers and other composites enable lighter, stronger modules that reduce transportation costs and expand architectural possibilities.

-

Integrated Smart Materials: Phase-change materials, self-healing concrete, and dynamic glazing systems can be more reliably incorporated in factory settings than on construction sites.

C.3. Transportation and Assembly Breakthroughs

Logistical innovations are overcoming the challenges of moving and connecting large building components.

-

Optimized Transportation Planning: Advanced routing software accounts for module dimensions, weight, and transportation regulations to minimize costs and disruptions during delivery to urban sites.

-

Robotic On-Site Assembly: Experimental systems use robotics for precise placement and connection of modules, reducing assembly time and improving safety.

-

Integrated Connection Systems: New joining technologies enable faster, more reliable connections between modules while maintaining structural integrity and environmental performance.

D. Urban Implications and City Transformation

The growing adoption of modular methods is reshaping urban development patterns and possibilities.

D.1. Urban Density and Land Use

Modular construction enables new approaches to urban intensification and land utilization.

-

Infill Development Acceleration: Modular methods make small-scale infill projects economically viable, activating underutilized urban parcels without requiring large-scale redevelopment.

-

Vertical Neighborhood Creation: Modular techniques facilitate mixed-use vertical development that combines residential, commercial, and community functions within single structures.

-

Temporary Use Activation: The ability to deploy and later relocate modular buildings enables temporary activation of sites awaiting permanent development, reducing urban blight and providing community benefits during interim periods.

D.2. Construction Process Urban Integration

Modular methods transform the construction experience for urban communities.

-

Reduced Neighborhood Disruption: Factory fabrication dramatically reduces noise, dust, truck traffic, and other disturbances typically associated with multi-year construction projects in dense urban areas.

-

Enhanced Construction Safety: Moving most construction activities to controlled factory environments significantly reduces worksite injuries, particularly important for projects in constrained urban locations.

-

Predictable Project Timelines: Reduced weather dependence and manufacturing precision enable more reliable project completion dates, minimizing extended neighborhood disruptions.

D.3. Economic and Labor Impacts

The modular transition is reshaping construction economics and workforce development.

-

Local Manufacturing Ecosystems: Modular construction can support local manufacturing jobs rather than relying on transient construction labor, providing stable employment in communities where buildings are deployed.

-

Skills Evolution: While reducing certain traditional construction trades, modular methods create demand for manufacturing, logistics, and digital design skills, potentially expanding and diversifying the construction workforce.

-

Development Economics: Reduced construction timelines decrease financing costs and enable earlier revenue generation, changing project feasibility calculations and potentially enabling more marginal projects to proceed.

E. Implementation Challenges and Evolving Solutions

Despite significant advantages, modular architecture faces implementation barriers that the industry is working to overcome.

E.1. Regulatory and Zoning Hurdles

Building codes and zoning regulations often lag behind modular innovations.

-

Standardization vs. Innovation Balance: Regulations must ensure safety while allowing innovation, requiring collaboration between modular manufacturers, design professionals, and code officials.

-

Transportation Infrastructure Limitations: Road networks, bridge clearances, and turning radii were not designed for transporting building-sized modules, requiring creative logistics and sometimes module size limitations.

-

Cross-Jurisdictional Coordination: Projects crossing municipal or state boundaries face varying regulations regarding transportation, manufacturing standards, and building approval processes.

E.2. Design and Coordination Complexities

Successful modular projects require rethinking traditional design and construction processes.

-

Early Decision Making: Modular construction requires resolving design details earlier in the process than conventional construction, challenging traditional sequential decision-making.

-

Systems Integration: Coordinating structural, mechanical, electrical, and plumbing systems across module connections demands sophisticated design coordination and tolerance management.

-

Architectural Expression Limitations: While advancing rapidly, modular construction still presents some constraints regarding irregular forms, complex geometries, and highly customized elements.

E.3. Industry Transformation and Adoption Barriers

The construction industry’s traditional structure presents adoption challenges.

-

First-Cost Perception Issues: Despite potential overall project savings, modular construction sometimes faces perception challenges regarding initial costs compared to conventional methods.

-

Supply Chain Development: Widespread modular adoption requires development of reliable supply chains for factory-based construction, which differ from traditional construction material supply networks.

-

Insurance and Financing Evolution: Lenders and insurers are still adapting their products and underwriting processes to account for modular construction’s different risk profile and payment schedules.

F. Future Directions and Emerging Possibilities

Modular architecture continues to evolve with new technologies, applications, and scales of implementation.

F.1. Technological Convergence and Advancement

Emerging technologies promise to further expand modular capabilities.

-

4D Printing Integration: Additive manufacturing technologies may eventually enable on-site fabrication of complex connection systems or custom components that complement factory-produced modules.

-

AI-Optimized Design: Artificial intelligence will increasingly guide module configuration for optimal performance, manufacturability, and transportation efficiency.

-

Blockchain for Supply Chain Transparency: Distributed ledger technology could provide transparent documentation of material origins, manufacturing conditions, and quality verification throughout the modular supply chain.

F.2. Scalability and Urban System Integration

Modular approaches are expanding beyond individual buildings to urban systems.

-

Modular Infrastructure: The principles of prefabrication and modular coordination are being applied to transportation, utility, and public space elements, creating integrated modular urban environments.

-

District-Scale Modular Planning: Entire neighborhoods are being conceived as modular systems where buildings, infrastructure, and public spaces are designed for coordinated prefabrication and assembly.

-

Climate-Responsive Modular Systems: Modules are being designed with integrated climate adaptation features that can be deployed where needed as climate impacts intensify.

F.3. Circular Economy and Lifecycle Evolution

The inherent adaptability of modular buildings supports circular economy principles.

-

Building Material Banks: Modular components designed for disassembly and reuse create valuable material inventories for future construction projects.

-

Performance Upgradability: Modular buildings can be more easily upgraded with new energy, water, or digital systems as technologies advance, extending building useful life.

-

Urban Mining Integration: As cities increasingly view buildings as material repositories, modular construction facilitates more efficient material recovery and redeployment.

Conclusion: The Modular Urban Future

The transformation of cities through modular architecture represents more than a construction methodology shift—it signals a fundamental rethinking of how we create and maintain the urban fabric. By bringing digital precision, manufacturing efficiency, and systematic thinking to the inherently messy process of city building, modular approaches offer solutions to some of our most pressing urban challenges: the need for rapid, dignified housing; the imperative to reduce construction’s environmental impact; and the requirement for buildings that can adapt to changing urban conditions. The most compelling modular projects demonstrate that efficiency and quality, speed and thoughtfulness, standardization and beauty need not be opposing values. As modular techniques continue to evolve and integrate with other technological advances, they promise to make our cities not just more efficiently built, but more responsive, more sustainable, and more humane. In this context, the modular transformation of construction represents not just an industry evolution, but a necessary reimagining of how we build the urban future.

Tags: modular architecture, prefabricated construction, urban development, sustainable building, construction technology, modular design, prefab architecture, building innovation, urban planning, construction methods, modular construction, smart cities