Digital Fabrication Revolutionizes Architectural Creation

The New Industrial Revolution in Architecture

The architectural profession is undergoing its most significant transformation since the Industrial Revolution, driven by the rapid advancement of digital fabrication technologies. This paradigm shift is redefining not only how buildings are constructed but fundamentally altering the design process itself, enabling unprecedented levels of complexity, precision, and customization. Digital fabrication represents the seamless integration of computational design with physical production, creating a direct pathway from digital models to built reality. As architects worldwide embrace these technologies, we’re witnessing the emergence of entirely new architectural languages, construction methodologies, and aesthetic possibilities that were unimaginable just a decade ago. This comprehensive examination explores how digital fabrication is reshaping architectural practice, from conceptual design to on-site construction, while addressing the profound implications for sustainability, labor, and the very nature of architectural creativity.

A. Historical Evolution: From Drawing Board to Digital Workflow

Understanding digital fabrication’s impact requires appreciating the technological journey that brought us to this transformative moment.

A. Pre-Digital Fabrication Methods

Traditional approaches that dominated for centuries:

-

Manual Craftsmanship: Reliance on skilled artisans interpreting two-dimensional drawings into three-dimensional reality.

-

Standardized Components: Industrial revolution introduced mass-produced building elements with limited customization.

-

Template-Based Construction: Physical templates and jigs for repeating elements across projects.

-

Scale Model Making: Physical models as primary means of visualizing complex geometries before construction.

B. The Digital Revolution Begins

Initial computer technologies that paved the way:

-

Computer-Aided Design (CAD): Transition from hand-drafting to digital drawing in the 1980s and 1990s.

-

CNC Machining Introduction: First computer-controlled manufacturing adapted for architectural components.

-

3D Modeling Software: Programs like Rhino and 3D Studio Max enabled complex surface modeling.

-

Early Rapid Prototyping: First-generation 3D printers for architectural model making.

C. The Contemporary Digital Fabrication Ecosystem

Current state of integrated digital workflows:

-

Building Information Modeling (BIM): Comprehensive data-rich models connecting design to fabrication.

-

Parametric Design Tools: Algorithms generating complex geometries directly linked to fabrication.

-

Robotic Fabrication Systems: Industrial robots adapted for architectural production.

-

Digital Material Libraries: Comprehensive databases linking digital models to physical material properties.

B. Core Digital Fabrication Technologies in Architecture

Several key technologies form the foundation of contemporary digital fabrication in architecture.

A. Additive Manufacturing (3D Printing)

Layer-by-layer construction revolutionizing architectural production:

-

Large-Scale Concrete Printing: Robotic arms depositing concrete in complex patterns without formwork.

-

Metal Additive Manufacturing: Printing structural metal components with optimized geometries.

-

Polymer and Composite Printing: Creating intricate architectural details and custom components.

-

Multi-Material Printing: Combining different materials within single printed elements.

B. Subtractive Manufacturing (CNC Technologies)

Computer-controlled material removal processes:

-

CNC Milling and Routing: Precisely cutting wood, metal, and composite materials.

-

Waterjet and Laser Cutting: Creating intricate two-dimensional components from various materials.

-

Robotic Carving: Complex surface treatments and ornamental details.

-

Stone and Glass Fabrication: Precision cutting of traditional materials with digital accuracy.

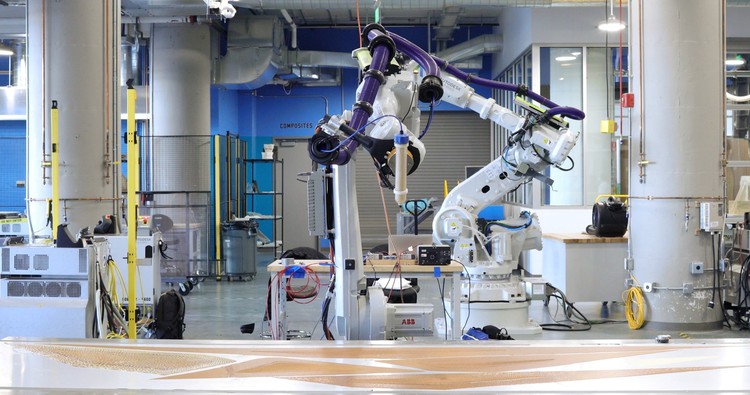

C. Robotic Assembly and Construction

Automated systems for component assembly:

-

Robotic Bricklaying: Automated masonry with complex patterns and mortar application.

-

Component Assembly Robots: Automated joining of prefabricated elements.

-

On-Site Robotic Construction: Mobile robots working in construction environments.

-

Human-Robot Collaboration: Systems where robots assist rather than replace human workers.

C. Transformative Applications Across Architectural Scales

Digital fabrication technologies are impacting architecture at every scale, from details to entire buildings.

A. Component and Detail Scale

Revolutionizing architectural elements:

-

Custom Joints and Connections: Highly specific structural connections optimized for loads and materials.

-

Architectural Ornament: Complex decorative elements economically produced in small quantities.

-

Integrated Building Systems: Components combining structure, services, and finishes in single fabricated elements.

-

Adaptive Formwork: Custom molds and formwork for unique concrete elements.

B. Building System Scale

Transforming how building systems are designed and fabricated:

-

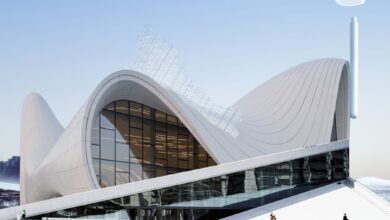

Custom Facade Systems: Building envelopes with unique geometries and performance characteristics.

-

Complex Structural Systems: Non-standard structural elements optimized for specific loading conditions.

-

Integrated Service Cores: Prefabricated units containing multiple building services.

-

Modular Construction: Factory-produced volumetric units with digital precision.

C. Urban and Landscape Scale

Larger-scale applications of digital fabrication:

-

Street Furniture and Public Art: Custom-designed elements for public spaces.

-

Landscape and Topography: Site-specific landforms and hardscape elements.

-

Temporary Structures: Rapidly deployed pavilions and event structures.

-

Infrastructure Elements: Custom-designed bridges, shelters, and public facilities.

D. The Design Process Transformation

Digital fabrication is fundamentally changing how architects work and think.

A. From Representation to Production

Shifting design mindset:

-

Design for Manufacturing: Considering fabrication constraints and opportunities from project inception.

-

File-to-Factory Workflows: Direct data transfer from design models to fabrication machines.

-

Material Intelligence: Understanding material properties and behaviors as integral to design.

-

Tolerance Management: Designing for specific fabrication tolerances and joint details.

B. New Creative Possibilities

Expanding architectural expression:

-

Complex Geometry Realization: Buildings and components with previously unbuildable forms.

-

Mass Customization: Economical production of unique elements rather than standardized components.

-

Material Exploration: New combinations and applications of traditional and innovative materials.

-

Performance-Based Design: Forms directly generated from environmental and structural performance criteria.

E. Sustainability and Economic Implications

Digital fabrication carries significant consequences for architecture’s environmental and economic dimensions.

A. Environmental Impact

Potential sustainability benefits and challenges:

-

Material Optimization: Using only necessary material through structural optimization and custom components.

-

Reduced Waste: Precision fabrication minimizing construction waste.

-

Local Production: Distributed manufacturing reducing transportation energy.

-

Lifecycle Considerations: Designing for disassembly and material reuse through digital documentation.

B. Economic Transformation

Changing cost structures and business models:

-

Reduced Labor Costs: Automation of repetitive and dangerous construction tasks.

-

New Skill Requirements: Demand for digital literacy alongside traditional construction knowledge.

-

Economic Accessibility: Lowering barriers for complex design execution.

-

Supply Chain Revolution: Shorter, more responsive manufacturing chains.

F. Case Studies: Pioneering Digital Fabrication Projects

Examining groundbreaking projects reveals the practical application and potential of these technologies.

A. The MX3D Bridge, Amsterdam

World’s first 3D-printed stainless steel bridge:

-

Robotic Printing Process: Industrial robots printing in mid-air without support structures.

-

Structural Innovation: Complex organic form optimized for material efficiency and structural performance.

-

Sensor Integration: Built-in sensors monitoring bridge performance throughout its lifecycle.

-

Public Engagement: Demonstration of digital fabrication’s potential to broad audiences.

B. The Bloom Pavilion, USA

A testament to algorithmic design and digital fabrication:

-

Parametric Design: Algorithmically generated form based on natural growth patterns.

-

CNC Fabrication: Hundreds of unique components precision-cut from flat sheets.

-

Manual Assembly: Digital components assembled using traditional techniques.

-

Material Efficiency: Minimal waste through nested cutting patterns.

C. The Gaobeidian Wood Pavilion, China

Large-scale robotic wood construction:

-

Robotic Timber Fabrication: Complex wood joints cut with robotic precision.

-

Traditional Material Innovation: Applying digital fabrication to timber construction.

-

Structural Performance: Algorithmic optimization of timber member sizing and orientation.

-

Cultural Integration: Blending digital technology with traditional woodworking culture.

G. Implementation Challenges and Limitations

Despite its potential, digital fabrication faces significant adoption barriers.

A. Technical and Practical Challenges

Overcoming implementation obstacles:

-

Scale Limitations: Physical constraints of fabrication equipment and material sizes.

-

Material Constraints: Limited range of materials suitable for current digital fabrication processes.

-

Technical Integration: Challenges of coordinating digital fabrication with conventional construction.

-

Quality Control: Ensuring consistency and reliability across digitally fabricated components.

B. Economic and Regulatory Hurdles

Financial and legal considerations:

-

Initial Investment Costs: Significant capital required for fabrication equipment.

-

Skills Gap: Shortage of professionals trained in both architecture and digital fabrication.

-

Building Code Adaptation: Regulatory systems struggling to accommodate digitally fabricated elements.

-

Insurance and Liability: New risk profiles for digitally fabricated structures.

H. The Future of Digital Fabrication in Architecture

Emerging trends and future directions for digital fabrication.

A. Technology Convergence

Multiple technologies combining for greater impact:

-

AI-Driven Fabrication: Machine learning optimizing fabrication processes and outcomes.

-

Augmented Reality Integration: AR systems guiding assembly of complex digital components.

-

Internet of Things: Embedded sensors in fabricated elements providing real-time performance data.

-

Blockchain Documentation: Secure, permanent records of digital fabrication processes.

B. New Material Frontiers

Advanced materials enabling new applications:

-

Smart Materials: Components that respond to environmental conditions.

-

Bio-Based Materials: Growing architectural components using biological processes.

-

Self-Assembling Systems: Materials that organize themselves into designed configurations.

-

Programmable Matter: Materials with dynamically alterable properties.

C. Societal and Professional Impact

Broader implications for architecture and society:

-

Democratization of Design: Increased access to complex architectural production.

-

New Business Models: Architecture practices integrating design and fabrication services.

-

Educational Transformation: Architecture schools incorporating digital fabrication into core curriculum.

-

Cultural Preservation: Using digital fabrication to restore and reproduce historical elements.

Conclusion: The New Architectural Reality

Digital fabrication represents more than just a new set of tools—it constitutes a fundamental reimagining of architectural possibility. By creating direct pathways from digital design to physical reality, these technologies are dissolving centuries-old boundaries between conception and construction, between designer and maker. The most successful architects of the coming decades will be those who embrace this integration, seeing digital fabrication not as a specialized service but as an essential aspect of architectural thinking.

The transformation extends beyond technical capability to touch the very essence of what architecture can be. Digital fabrication enables architectures of complexity and variation rather than repetition and standardization. It allows buildings to be more responsive to their specific conditions—environmental, cultural, and functional. And it opens possibilities for architectural expression that reflect the complexity and richness of contemporary life while addressing urgent challenges of sustainability and resource efficiency.

As the technology continues to advance and become more accessible, we’re likely to see digital fabrication evolve from cutting-edge innovation to standard practice. The buildings of our future will increasingly be computed and fabricated as much as they are drawn and constructed. In embracing this future, architects have the opportunity to create a built environment that is more precisely tailored to human needs, more respectful of planetary limits, and more expressive of architectural imagination than ever before. The digital fabrication revolution in architecture is just beginning, but its impact promises to reshape our world in profound and lasting ways.

Tags: Digital Fabrication, Architectural Technology, 3D Printing, Robotic Construction, Computational Design, Parametric Architecture, Building Innovation, Sustainable Construction, Digital Manufacturing, Architectural Robotics